© Copyright by mimatic GmbH 2017 | 沪ICP备16046075号-2 | Impressum | Datenschutz | Newsletter abonnieren

特定组件的解决方案

-

组件特定的完整解决方案

Component Part Specific Complete Solutions

of driven tool holder and cutting edge

Ask us – we gladly accept the challenge and develop together with you a solution in the areas of:

- Multi spindle solutions

- Saw blade holders

- Fixed angle

- Plunge milling in cavities of larger components

- Complete solutions with cutting tools

组件特定的完整解决方案

动力刀座,角度头,和刀柄,刀具

询问我们 - 我们乐意接受挑战,并与您共同开发以下领域的解决方案:

多主轴解决方案

锯片支架

固定角度

在较大组件的凹腔中进行切入铣削

切割工具的完整解决方案

-

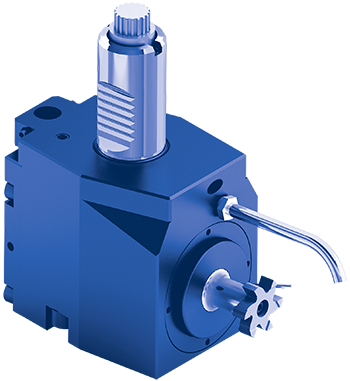

带硬质合金刀片接口的紧凑型刀柄

Compact Driven Toolholders with Interface for Carbide Inserts

Thanks to mimatic‘s cross-system expertise in the fields of driven tool holders and precision carbide steel cutting tools, mimatic has developed a compact new cutting solution.

The interfaces and holders that are usually located between the powered tool and circular milling insert are eliminated. Directly on the main shaft of the powered tool there is now the polygonal insert fixture for the cutting of threads, grooves and cut-ins.

This provides the following advantages: Due to the exclusive use of only one highly-accurate polygonal interface, the true running is improved and the service life is increased. The insert in the machine can be changed using only one screw. Thanks to planar arrangement and self-centring, there is no need for measuring and pre-adjustment! AGMILL thus offers resource efficiency and sustainability.

带硬质合金刀片接口的紧凑型刀柄

得益于mimatic在驱动刀架和精密硬质合金钢领域的跨系统专业技术凭借mimatic在驱动刀架和精密硬质合金钢刀具领域的跨系统专业技术,mimatic开发了一种紧凑型新型切割解决方案。

通常位于电动工具和圆形铣削刀片之间的接口和支架将被取消。直接在电动工具的主轴上,现在有用于切割螺纹,凹槽和切口的多边形插入式夹具。

这提供了以下优点:由于仅专用一个高度精确的多边形界面,所以真正的运行得到改善并且使用寿命增加。机器中的插件只能使用一个螺钉进行更换。由于平面布置和自动对中,不需要测量和预调整! AGMILL因此提供资源效率和可持续性。

-

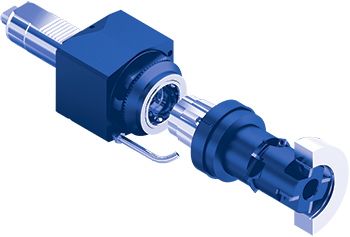

集成的工具解决方案

The Integrated Tool Solution

For more efficient machining on turning machines, mimatic applies its expertise in integrated and complex cuttting tools and its expertise in driven tool holders. The result is a cross-system tool solution for series production.

The central part of this solution is the modular quick-change interface mi, which connects the driven tool holder directly and without additional work to e.g. shell-type milling tools for combined machining (turning, planing, chamfering).

A minimal tool-changing time is achieved with quick-change singlehand operation in the machine. Planar arrangement, symmetrical 3-point intake and a short taper rule out operation errors! The compact mi cutting tool designed for the interface requires no pre-adjustment.

The mi cutting tool has a solid, onepiece construction with integrated mi quick-change interface and reduces constructed size and true running errors.

mi-System offers increased efficiency, sustainability and the saving of resources.

集成的工具解决方案

为了在车床上进行更高效的加工,mimatic将其专业知识应用于综合和复杂的切割工具以及其在驱动刀架方面的专业技术。其结果是用于批量生产的跨系统工具解决方案。

该解决方案的中心部分是模块化的快速更换接口mi,它直接连接被驱动的刀架并且不需要额外的工作。用于组合加工(车削,刨削,倒角)的壳式铣削刀具。

在机器中快速更换单手操作即可实现最短的换刀时间。平面布置,对称3点进气和短锥度排除操作错误!为界面设计的紧凑型mi切割工具不需要预先调整。

mi切割工具具有坚实的一体式结构,集成了mi快速更换接口,并减少了构造尺寸和真实运行错误。

mi-System提供更高的效率,可持续性和资源节约。

-

锯片铣刀,动力刀座完整解决方案

Turn Cut Milling with PolySAWShort process timesProcess reliabilityMaterial savingSurface qualityAbsence of burrsShort chipsThe new process technolo

Turn Cut Milling instead of parting off: Faster parting off than anybody else!

- Short process times

- Process reliability

- Material saving

- Surface quality

- Absence of burrs

- Short chips

The new process technology from mimatic is called Turn Cut Milling with PolySAW: Turn Cut Milling instead of parting off! This is the combined know how of live tools and cutting tools by mimatic.

PolySAW turn cut milling is enabled by the new QUADROGON interface developed by mimatic. Quadrogon safely and reliable transmits the high performance during Turn Cut Milling.

The high number of cutting-teeth of the PolySAW milling cutter also has a positive effect when machining asymmetric or thin components. Due to its continuous and uninterrupted tooth engagement and the resulting smooth machining process.

PolySAW milling cutters may look like conventional saws on first sight, however, mimatic has provided PolySAW with all the properties of high-value milling tools. The process reliability and performance of PolySAW is unmatched by conventional saws.

• 处理时间短

• 过程可靠性

• 节省材料

• 表面质量

• 没有毛刺

• 短筹码

来自mimatic的新工艺技术被称为使用PolySAW的切割铣削:切割铣削而不是分离! 这是由mimatic组合了解实时工具和切割工具的知识。由mimatic开发的新型QUADROGON界面支持PolySAW切割铣削。 Quadrogon安全可靠地传递切削铣削期间的高性能。

PolySAW铣刀的大量切齿在加工非对称或薄壁零件时也具有积极作用。 由于其连续且不间断的齿啮合以及由此产生的平滑加工过程。

PolySAW铣刀可能看起来像传统的锯,但是,mimatic已经为PolySAW提供了高价值铣刀的所有特性。 PolySAW的工艺可靠性和性能是传统锯无法比拟的。